Multi-parameter online water quality monitor is a kind of water quality equipment that can simultaneously monitor a variety of water quality parameters such as pH value, dissolved oxygen, turbidity, ammonia nitrogen, total phosphorus, total nitrogen, heavy metals and other parameters.

1. Product Introduction

1.1 Overview

The QSZ03 water intake quality monitoring microsystem is a comprehensive sensor acquisition, display and analysis system based on the Internet of Things technology. The water supply quality monitoring microsystem consists of a steady flow exhaust unit, an analysis and testing unit, a system control unit and a remote communication unit, and has complete power supply, lightning protection, network communication and other functions.

1.2 Product Positioning

The QSZ03 water quality monitoring microsystem has an automatic monitoring function. The main monitoring items of the integrated extraction micro water quality automatic monitoring station are: water temperature, conductivity, and PH. It uses highly integrated technology to achieve automatic water quality monitoring functions in one cabinet.

The equipment can be widely used for online monitoring of water quality in urban or rural water plants, water supply networks, secondary water supply, user terminals, indoor swimming pools, large water purification equipment and direct drinking water. It is an indispensable online analysis equipment in the fields of water plant production process control, water conservancy and water affairs management, and health supervision.

1.3 Functions and Features

GPRS 4G

Support extended RJ45 networking

Support extended sensor remote transmission

Support LED screen display 7.0 inch touch control screen

Supports extended Android screen display and storage

Expanded Android screen supports 2G data storage and USB data export

Support one RS485 modbus-RTU protocol slave station

Support multi-channel RS485 modbus-RTU sensor expansion

Supporting IoT data display, storage and analysis platform

The platform supports TCP short link, HTTP protocol and other protocol data forwarding

2. Composition

2.1 Components

The water quality monitoring microsystem consists of a power supply unit, a water pump control unit, an analysis and testing unit, a display unit, a water pump unit, a remote communication unit and an integrated box main unit.

2.1.1 Power supply unit

Power adapter AC220 to DC12V/3A.

2.1.2 Water pump control unit

DC12V 30W intelligent self-priming pump Maximum head: 40m Opening flow: 2.8L/min

2.1.3 Analysis and testing unit

The analysis and testing unit is mainly composed of water temperature, conductivity, and pH sensors, which are fixed on the flow cell by threads or tight fittings. The main parameters of the sensors are as follows:

Technical Parameters

| 4Serial Number | name | Measuring range | Measuring principle | Measurement accuracy | Is it standard? | Remark |

| 1 | temperature | 0~50℃ | High-precision digital sensor | ±0.3℃ | ✔ |

|

| 2 | pH | 0~14 (ph) | Electrochemistry (Salt Bridge) | ± 0.1PH | ✔ |

|

| 3 | Conductivity | 0~5000uS/cm | Contact electrode method | ± 1.5% | ✔ |

|

| 4 | Turbidity | 0~40NTU (low turbidity) | Scattered light method | ± 1% |

|

|

| 5 | Dissolved oxygen | 0~20mg/L | Fluorescence lifetime method | ± 2% |

|

|

| 6 | Ammonia nitrogen | 0~100mg/l | Ion Selective Electrode Method | ±1mg |

|

|

| 7 | cod | 0~500mg/L | UV254 absorption method | ±5% |

| Equipped with an automatic cleaner to prevent biological attachment and avoid light window pollution to ensure long-term monitoring stability; the automatic cleaning time and cleaning frequency can be set, power consumption is 0.7W |

Note: The sensor cannot be installed upside down or horizontally, but must be installed at an angle of at least 15 degrees.

The working environment of the above water quality sensors is 0-50℃, <0.3Mpa.

2.1.4 Display unit

Multi-parameter monitor, installed on the cabinet door, performs data collection, analysis, display, communication and data storage operations

·Android version: 4.4.2·CPU: Quad-core Cortex™-A7·RAM/ROM: 512M/4G·Screen: 7-inch capacitive touch screen·Power supply: 12V/1A·Support USB expansion, support memory card expansion

2.1.5 Remote Communication

RS485 interface MODBUS-RTU communication protocol Factory device address 6 decimal Support 03 function code to read data

| parameter | Decimal address | Hexadecimal address | Data Types |

| Parameter 1 | 40001 | 0x0000H | 16-bit integer |

| Parameter 2 | 40002 | 0x0001H | 16-bit integer |

| Parameter 3 | 40003 | 0x0002H | 16-bit integer |

| Parameter 4 | 40004 | 0x0003H | 16-bit integer |

| Parameter 5 | 40005 | 0x0004H | 16-bit integer |

| Parameter 6 | 40006 | 0x0004H | 16-bit integer |

Sort by order

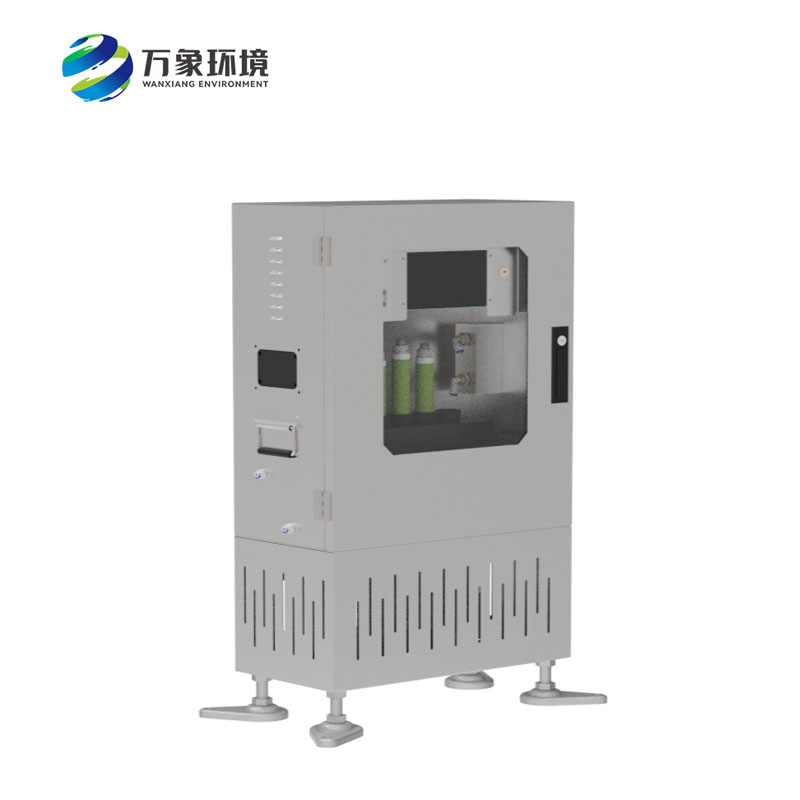

2.1.6 Equipment box main unit

| Product Name | Water quality monitoring microsystem |

| Installation | The cabinet is installed on the ground, with a base. |

| Dimensions | 850mm*500mm*250mm 50-100mm adjustable |

| Shell material | 304 stainless steel. |

| Protection level | IP54 |

| powered by | AC220V internal power adapter AC220 to DC12V/3A |

| Water Inlet | 2-point water purifier PE pipe with an outer diameter of φ6.5, flow rate 500mL/min, pressure 0.1-0.2MPa |

| Water outlet | 2-point water purifier PE pipe with an outer diameter of φ6.5, flow rate 400mL/min |

| Sewage outlet | 2-point water purifier PE pipe with an outer diameter of φ6.5, flow rate 100mL/min (manual regular drainage is also possible) |

| Self-priming pump | Motor speed: 2800r/min |

| Rated voltage: DC 12V |

| Maximum current: 2.5A |

| Maximum suction lift: 1.5m Maximum lift: 40m |

| Opening flow: 2.8L/min Protection pressure: 0.4Mpa |

| Supporting sensor (optional) | PH: 0-14 Dissolved oxygen: 0-20mg/L Turbidity: 0-40NTU Conductivity: 0-5000us/cm Temperature: 0 °C ~ 50 °C |

3. Product size

4. Equipment Installation

Overall diagram of the equipment Schematic diagram of the internal measurement unit

Cycle detection time setting (factory setting is recommended) The faster the cycle time, the shorter the service life of the controllable device.

4.1 Equipment Installation Process

4.2 Site Investigation

The purchaser's on-site environmental survey includes the determination of various on-site conditions (such as installation points, water intake points, point distances, power cables, pipe trenches, etc.).

4.3 Preparation before installation

The purchaser is responsible for implementing the preparatory work before installation, including confirmation of the location of the water intake point and the installation point, construction of the cement foundation of the installation point, introduction of power cables, laying of pipeline trenches and basic civil construction.

4.4 Installation and debugging

Carry out installation and commissioning, including equipment installation, pipe laying, calibration and commissioning. The buyer contacts the supplier for technical assistance in commissioning.

4.5 Installation point distance confirmation

Distance from water intake point to shore: horizontal distance cannot exceed 10 meters, height difference cannot exceed 5 meters;

Distance from the shore to the water station: the horizontal distance cannot exceed 10 meters, and the height difference cannot exceed 5 meters;

4.6 Installation point basic preparation

Survey the geological conditions. If the surface is soft soil, it is recommended to re-survey the site or dig 0.5 meters above or below the original site before pouring concrete. At the same time, it is necessary to confirm whether there are other facilities below the excavation location (such as cable pipelines, etc.)

For cement foundation construction, the foundation size is 1.5m*1.5m, and the height of the foundation top from the original ground is 0.2m; C20 or above concrete formwork is used for casting and fixing to ensure the overall density and firmness. Water and maintain the concrete regularly during the solidification process. Equipment can be installed after the concrete is completely solidified (generally more than 72 hours);

Water station foundation

(1) Excavation of pipeline trench (as shown in Figure 3). The trench size is 30 cm below the ground and the width is 40 cm. The pipeline is generally divided into two sections: the ground section and the buried section (see Figure 3).

(2) If the excavation site encounters asphalt or concrete ground, the road surface needs to be restored;

(3) Ground section: The pipeline is laid with insulation cotton on the outer layer to achieve the corresponding insulation and anti-freeze functions;

(4) Buried section: The pipeline is laid below the local permafrost layer to protect it from freezing.

4.7 Power requirements for installation points

Voltage: 220V AC±10%;

Frequency: 50 Hz ± 5%;

Lead the power supply that meets the requirements to the water station installation location.

4.8 Login Platform

Cloud platform large screen display can be cast (http://47.92.208.0)

The experience account is Test FT.com, and the default password is 123456

Device data

5. Maintenance

When using for the first time or after a long period of disuse,

The pH sensitive bulb and reference junction should be immersed in 3.3 mol/L KCl solution for more than 2 hours.

When using, it should be washed with deionized water (or distilled water) and wiped dry to prevent impurities from entering the measured liquid. 1/3 of the sensor should be inserted into the measured liquid. The terminal part should be kept clean and dry. The sensor should be cleaned when not in use, and inserted into a protective cover with 3.3mol/L KCI solution, or the sensor should be inserted into a container with 3.3mol/L KCI solution. Check whether the terminal is dry. If there are stains, please wipe it with anhydrous alcohol and continue to use it after drying. The sensor should avoid being immersed in deionized water, protein solution, strong acid and alkali solution, and acid fluoride solution for a long time, and prevent contact with silicone grease. The glass membrane of the sensor that has been used for a long time may become translucent or have sediment. At this time, it can be washed with dilute hydrochloric acid and rinsed with water. When the sensor has been used for a long time and measurement errors occur, it can be calibrated and corrected by cooperating with the instrument. When the sensor cannot be calibrated and measured after the above methods are maintained and maintained, it means that the sensor has failed. Please replace the sensor.

Conventional conductivity electrodes need to be cleaned and calibrated periodically. The maintenance cycle is determined by the customer based on their working conditions. Conventional electrode cleaning method: Use a soft brush to remove attachments (be careful to avoid scratching the electrode surface), then clean with distilled water, and then perform calibration operations.

The ORP sensitive bulb and reference junction should be immersed in 3.3 mol/L KCl solution for more than 2 hours.

When using, it should be washed with deionized water (or distilled water) and wiped dry to prevent impurities from entering the measured liquid. 1/3 of the sensor should be inserted into the measured liquid. The terminal part should be kept clean and dry. The sensor should be cleaned when not in use, and inserted into a protective cover with 3.3mol/L KCI solution, or the sensor should be inserted into a container with 3.3mol/L KCI solution. Check whether the terminal is dry. If there are stains, please wipe it with anhydrous alcohol and continue to use it after drying. The sensor should avoid being immersed in deionized water, protein solution, strong acid and alkali solution, and acid fluoride solution for a long time, and prevent contact with organic silicone grease. If the platinum sheet of the electrode is stained with grease, it can be gently wiped clean with absorbent cotton dipped in acetone or alcohol. If the contamination is an insoluble inorganic substance, it can be scrubbed with 30-50% hydrochloric acid. It can also be wiped once a day with clean high-grade toilet paper. When the sensor has been used for a long time and measurement errors occur, it can be calibrated and corrected by using the instrument. If the sensor cannot be calibrated and measured after the above maintenance and care, it means that the sensor has failed. Please replace the sensor.

Dissolved oxygen sensor outer surface: Rinse the outer surface of the sensor with clean water. If there is still dirt remaining,

Please wipe with a damp soft cloth. For some stubborn dirt, you can add some household detergent to the water to clean it. Fluorescent membrane head surface: If there is dirt on the surface of the fluorescent membrane head, please rinse it with clean water or wipe it gently with a soft cloth. Pay attention to the strength when cleaning to avoid scratching the measuring area and affecting the measurement accuracy. Avoid the inner surface of the fluorescent membrane from being exposed to sunlight or strong light. Do not touch the fluorescent membrane with your hands or sharp objects. Avoid bubbles on the surface of the fluorescent membrane when using it.

Turbidity sensor maintenance: If the sensor needs to be cleaned, it can be cleaned with warm water and an appropriate amount of detergent.

Note: Avoid strong vibrations that damage the front transparent glass, and do not scratch it with hard objects.

Routine maintenance items

To ensure the normal operation of the monitor and to detect potential faults as early as possible, the monitor should be regularly checked on a daily basis. The monitor does not require special maintenance, but it must be kept clean.

The items for routine inspection and the recommended inspection frequency are given in the table.

Daily routine inspection list

| Serial number | Routine inspection contents | Normal situation description | Recommended frequency |

| 1 | Is the monitor appearance clean? | Clean appearance | 1 time/month |

| 2 | Is the time setting correct? | The time and date are correct | 1 month/time |

| 3 | Is the grounding of the monitor good? | There is no obvious voltage between the casing and the ground | 1 month/time |

| 4 | Are the sensor parameters set normally? | Refer to the sensor technical documentation | 1 month/time |

| 5 | Is the communication normal? | normal | 1 month/time |

| 6 | Are other devices damaged? | normal |

|

Product address:

http://www.qxhjjc.com/en/shuizhi/1189.html

Home

Home phone

phone Product Overview

Product Overview Contact Us

Contact Us