In the field of industrial production and storage, safety is always a core issue that cannot be ignored. Especially in the flammable and explosive environment, any small meteorological change may cause serious safety accidents. In order to effectively deal with this challenge, explosion-proof monitoring system came into being. This meteorological monitoring station, which integrates high-tech and security, has become an important tool to ensure the safety of industrial production and storage with its excellent performance and accurate data monitoring capabilities.

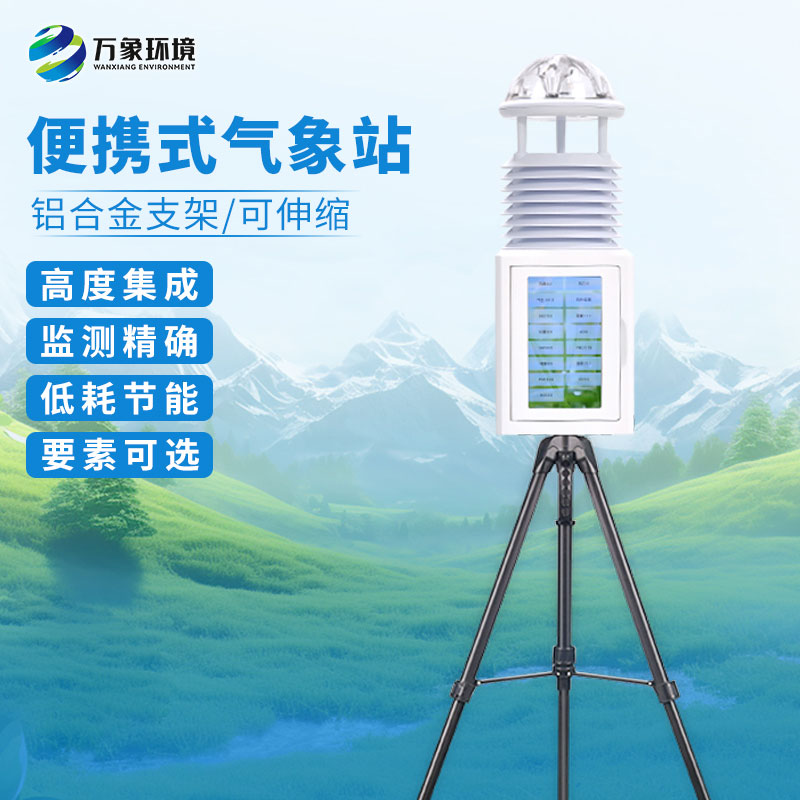

WX-FBQ1 explosion-proof monitoring system adopts advanced explosion-proof technology and design concept to ensure safe and stable operation in flammable and explosive environments. The main body of the system is usually composed of explosion-proof shell, high-precision sensor, data processing unit and communication module. These components are strictly explosion-proof certified to maintain stable performance in extreme environments and prevent explosive accidents caused by electrical sparks or high temperatures.

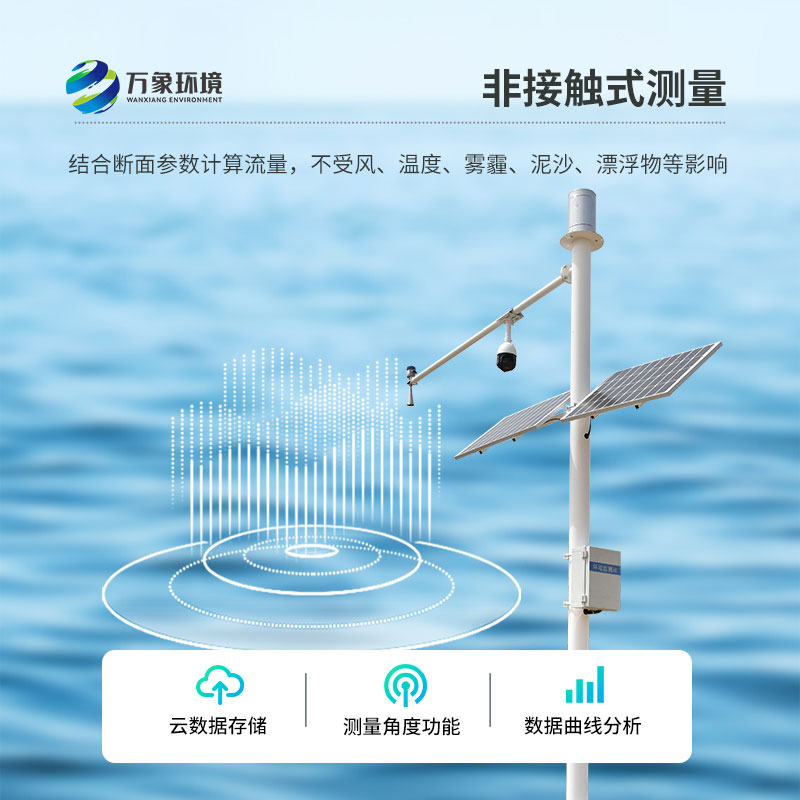

In terms of sensors, the explosion-proof monitoring system is equipped with a variety of high-precision meteorological sensors, including temperature sensors, humidity sensors, air pressure sensors, wind speed and direction sensors. These sensors can monitor key meteorological parameters such as temperature, humidity, air pressure, wind speed and direction in the environment in real time, and transmit the data to the data processing unit for analysis. Through accurate data monitoring and analysis, the system can find potential safety hazards in time, providing a strong guarantee for safe production.

In practical application, the explosion-proof monitoring system shows its unique advantages. The system can monitor the weather change in the flammable and explosive environment in real time, and discover the potential safety hazards in time. When abnormal meteorological parameters are detected, the system will immediately issue an alarm message to remind users to take corresponding measures. This real-time safety early warning function can greatly reduce the probability of safety accidents and ensure production safety.

Article address:

http://www.qxhjjc.com/en/article/1326.html

Home

Home phone

phone Product Overview

Product Overview Contact Us

Contact Us